Light Emitting Diode (LED) grow lights are a type of energy efficient lights that are an option for indoor growers. Unlike other types of grow lights, LEDs do not burn a filament, but instead pass light through semiconductors to create their spectrum. LED grow lights can be used as the sole means of lighting in a growing operation, as a supplement to natural light, or paired with other types of grow lights.

Unlike other types of grow lights, light emitted by LEDs can be focused, so that none is dispersed or lost between the bulb and the canopy of the plants. LEDs have long service lives, with bulbs lasting from 50,000 to 100,000 hours of continuous use.

LED grow lights have gone through a number of improvements to get to where they are today, so it makes sense that many growers are wary of them. On the flip-side, HIDs have been around much longer than LEDs and have become a tried and true way to grow indoors. In the end, though, LED grow lights have proven their efficiency and effectiveness in the grow room. Here’s why:

Low Heat Generation — LED grow lights are the only lights around that don’t need to heat up metal or gases to extreme temperatures, unlike HIDs. That energy and the heat created by it are why HIDs get so hot and end up adding heat to your grow room. The heat from the radiation that LEDs emit is minimal — nowhere near the heat generated by HID lights. This heat is more of a nice addition to your garden compared to an HID’s heat, which can create stressful, overheated conditions for your plants if not regulated.

Low Energy Consumption — LEDs use much less energy to run than HIDs. LEDs give you the same amount of PPFD as an HID twice its wattage, and you won’t need to regulate its heat. Cooling and ventilation equipment will need to work less with LEDs, which will reduce your energy consumption even further.

Pinpointing Vital Wavelengths Plants Need — LED grow lights are great at giving plants the specific wavelengths of light beneficial to growth. Plants only absorb certain wavelengths of light, so the drawback to HIDs and T5s is that plants waste a lot of the light their broad spectrums provide. LEDs have the ability to pinpoint and increase the availability of various blue and red wavelengths — even infrared and ultraviolet wavelengths — your plants need so they get as many usable wavelengths as possible.

There are LEDs that offer you all white spectrums of light just like CMH grow lights, as well as warm and cool spectrums like HIDs and T5s. No matter what style of light you’re used to or want to try, you’ll be able to find an LED grow light with the spectrums of light you need to get your plants where you want them to be.

LED Grow Lights Inside and Out

While LED grow lights (electronic) may operate in a different way than HIDs (chemical), they’re essentially made with the same parts. You have the diode that emits light like a bulb, a driver that transfers energy to your diodes like a ballast, and the housing of your LED which acts more or less like a reflector.

With that in mind, let’s break down the major components of a grow light: diodes, power supply, and housing.

Diodes

A diode is what’s used to translate electricity to visible light in an LED. While a diode itself contains lots of different parts (like wires, heat sinks, and bases), we’ll focus on the main components in the diode: the chip and the lens.

Chips

Chips are the surfaces that electricity runs across to give us light. The brightness of a diode is based on the strength and number of chips inside, and each of those chips has a wattage it takes to give off light.

Most LEDs use .5w, 1w, 3w, and 5w chips that offer you a certain amount of lumens. The more lumens a chip can give off, the brighter the diode will be. The more diodes you have, the stronger the overall LED grow light will be. And the more lumens a light has, the better it will be at penetrating your plants’ canopy for vigorous growth.

It should be noted that the more chips you have on a diode’s surface, the higher the lumen output will be out of a diode. For example, COB chips work by using a lot of little, low wattage chips (around .25 to .5w) on a relatively small surface. All of these tiny chips come together to give you a super bright light, even with a phosphor cover.

Dying and Covering Chips — Chips are usually (but not always) dyed to give off a certain color that mimics a particular wavelength of light along the light spectrum. Non-programmable diodes are dyed the color they should be, whereas diodes in adjustable LEDs are dyed blue, red, and green. The particular color combination will allow you to get white, blue, red, green, and violet wavelengths that plants need.

Whether they’re dyed or not, a small phosphor cover is placed on the chips to dampen the piercing light that electricity gives off from the chip. In the case of ultraviolet diodes, the chip cover is made of crystals like sapphire to offer that intense wavelength when light radiation is offered. Infrared diodes, on the other hand, have secondary internal reflectors that filter light coming out so that only IR wavelengths of light are emitted.

Lens

The lens covering each diode helps focus the light coming from each chip so that it doesn’t emit into the open air unfocused and ineffective. This lens is what facilitates the intensity of the light given off by the chip. Therefore, the type of lens a diode has will help determine how the light is focused down onto your plants.

Contrary to popular belief, the beam angle (or the width of the beam of light coming out) doesn’t depend solely on the type of lens used. Rather, it comes from how close a chip is to the lens. The further a chip is from the lens, the more narrow and intense the light will be coming from the diode. The closer the chip is to the lens, the wider and softer the beam of light will be. Here’s what this idea looks like in real life:

180° beam angles are achieved with simple protective covers over chips. The spread on these lights is wide, giving you a big lighting area that can cover lots of plants. Though that wide coverage area isn’t filled with intense PPFD, getting more intensity you’ll only requires more chips and/or higher wattage chips. That’s why spread-style LEDs are the most common lights that offer 180° angles, as they contain hundreds of smaller low wattage chips that cover wide canopies with soft but effective light.

90° beam angles start out with thick, domed lenses. The chip of a 90° beam is raised close to the dome of the lens to offer a wide but intense beam of light down onto your plants. These are traditionally used on COBs and traditional lights because of their ability to spread light while focusing lots of it down onto plants for intense growth.

60° beam angles come from the same thick lenses, only this time the chip sits around halfway between the chip and the top of the lens. This beam of light is more narrow, and while it does offer much more intensity for your plants than 180° and 90° beams, it also offers less coverage area. If you’ve ever seen an LED that touts extreme intensity, chances are the light produces 60° beam angles or offers a dual lens.

Dual lens diodes contain two lenses: the primary lens, which gives your plants an initial 90° beam angle, and the secondary lens, which takes that 90° beam and intensifies it by focusing it into a 60° beam. This intensity helps canopy penetration from far distances.

Diode Arrangement

Diodes on an LED grow light are arranged in certain combinations to ensure it works properly depending on the drivers used. There are two types of arrangements: panels and diode clusters.

An LED panel consists of diodes (usually with 180° beams) wired together and mounted directly to a panel, all illuminating when activated. Supplemental lights are a single panel of low-wattage chips mounted to a surface, whereas standalone lights consist of multiple panels outfitted with a number of 3w chips each. Usually in these arrangements, if one diode goes out, the entire panel will go out.

Diode clusters arrange diodes (usually with 90° and/or 60° beams) in a circular or rectangular shape and place them around the light. These are mostly used in standalone lights because you can fit a number of high-powered diodes into these clusters, and a number of these clusters in a grow light. However, you can find these clusters used in supplemental lights, and each cluster gets its own power supply.

A Quick Note on Bleaching and Leaf Burn

While LED grow lights may not produce heat, the light they do produce is intense. Remember that the light coming from LEDs is the result of electricity, and raw electricity is extremely bright, which is why it needs to be buffered by a cover and lens.

The problem with LEDs is that regardless of how much you dampen chips, the light produced is still super intense. As such, lights that are too close to plants can actually bleach them. When this happens, light damages the chlorophyll in the leaves, flowers, and fruit your plant produces. When chlorophyll is destroyed, plants have a hard time taking in light and breaking it down to use as energy. The plant will usually continue to grow, but it will be weaker, and the color you love on your plants will definitely be tarnished.

We should also mention that while the heat produced by LEDs is very minimal, the electric radiation they create produces heat. Thankfully, lenses and covers help insulate some of that heat, but when plants press up against diodes that’ve been on for hours, there’s a chance the diodes can get extremely hot and start to burn a plant. Some burns can be simple discoloration and damage, while sustained burning can lead to combustion if not mediated.

Fortunately, bleaching and burning are remedied simply by hanging your plants at the right height, which is anywhere between 18in and 30in above plants.

Power Supply

The power supply, or driver, of all LED grow lights is essentially the brains. The driver is what helps regulate the voltage coming into the light so that it doesn’t overpower each diode and cause shorts. It’s also responsible for protecting LEDs from power fluctuations that can cause your light to short.

The type of driver used depends on how much power it needs to regulate. There are internal and external drivers that help various types of grow lights depending on the strength of the chips it will need to power.

Internal drivers are small but capable of powering a good amount of chips. They’re commonly used for lower wattage grow light panels like the 50 Watt Advance Spectrum Dual Band LED Grow Light Panel that have one hundred .5w chips, but can be found in higher wattage lights like 100w COBs with one 100w diode.

External drivers are capable of powering many more chips at much higher wattages. For example, each diode cluster in the S180 Advance Spectrum MAX LED Grow Light Kit requires its own external driver. That’s because each cluster contains fifteen diodes with 3w chips, including UV and IR that require a special considerations. Large panels like those from Black Dog LEDs need to power hundreds of 3w and 5w chips across a number of panels, so they also use external drivers.

Because external drivers take in and distribute so much energy, they have built-in heat syncs and even power fans to keep cool.

Housing

LED grow lights don’t use traditional reflectors like HID and T5 grow lights do. For the most part, they don’t use reflectors at all. Instead, each driver, diode cluster, and panel is housed in a shell. The shell offers openings for the diodes and chips to emit light from, while offering a white or silver reflective background to help reflect the light each diode emits down onto your plants.

There are benefits and challenges to using LED grow lights with shells:

If you have a more complicated light — say, a dimmable LED grow light with lots of diode clusters that have their own drivers — shells will help keep all that technology safe from dust and moisture found in the open air. They’re also made with air vents to help air flow to prevent overheating.

LED grow lights without shells, from supplemental lights to high-powered ones, tend to be more minimal in design. When working with these lights, make sure to keep an eye on the moisture and dust around the light. They’ll work as well as lights with a shell, but keep in mind that they’re more exposed to the environment.

You shouldn’t be swayed one way or another about a light based on whether it has a shell. Ensuring drivers are able to safely operate and give your diodes energy is just as important, and that will depend on whether your light has a shell or how clean you keep the area around drivers and diodes.

Types of LEDs

Now that you know what LED grow lights are made of, let’s talk about the types of LEDs that are out there for you. There are a lot of styles with their benefits and challenges, so let’s dive into the types of LEDs you can choose from.

Traditional

Traditional LED grow lights are an industry standard these days. They’re some of the most reliable LEDs on the market, with individual drivers controlling up to 100w per cluster.

Out of all LEDs, traditional lights have the most versatility. Each diode in a traditional LED has 1 to 5w chips depending on the strength of the overall light, with 1 to 2 lenses helping project light. A single lens will a light to give you a 90° focus beam of light, and a secondary lens would give you an extra 60° of focus to intensify that further.

These lights also have the widest spectrum availability. From cool and warm temperatures like T5s to deep purples all the way to UV and IR lighting, there’s virtually no wavelength of light that traditional LEDs can’t give you.

As great as they are, traditional LEDs can be on the heavy side. The stronger the light, the more equipment is used, which adds weight to the light. Any light falling on your plants will harm them, but a high-powered traditional LED like the S900 Advance Spectrum MAX LED Grow Light Panel that weighs over 30 lbs crashing down onto your plants will annihilate them, no question.

So when you’re going the traditional route, focus on two things: ensuring it has the spectrums of light your plants need, and that your grow room is equipped to handle at least 25 to 30 lbs securely.

Spread

Spread-style LED grow lights get their name from the way the diodes on them are spread across their surface. They’re relatively inexpensive compared to other LED grow lights, and just as effective despite their limited wavelength offerings.

The chips in spread-style LEDs tend to be low, but with the number of diodes on each panel, the possibilities of reaching a high lumen output are virtually endless. That’s because of two key structural factors:

Each diode contains a single .25 to 1w chip. With an average lumen output of 60 lumens per watt, a simple 50w panel with 50 chips can give you 3000 lumens of light — that’s more intense than a 54w T5 6400k bulb.

Spread LEDs usually don’t use domed lenses. This frees up space on each panel to fill with as many diodes as possible. This will both increase the overall intensity of the LED and increase the light footprint it casts.

While they have the possibility for wide, even light coverage, that coverage tends to be less focused than with other LEDs. This results in softer coverage, requiring many more diodes to increase power. When using spread LEDs, be sure you have plenty of room to adjust their height as needed. If you don’t have the room to raise your lights, make sure the spread LED you choose offers a dimming feature.

COB (Chip on Board)

COB stands for “chip on board”, and it’s called that because of the construction of the diodes. Each diode contains many tiny, low-wattage chips that shine together to give you a super charged light out of a single diode.

50w COB diodes, for example, usually have fifty mini 1w chips on one small surface, giving you around anywhere from 3000 to 5000 lumens out of a one diode. That’s right — the same intensity you’d get out of a fifty 1w chips on a larger panel, you can get out of one COB diode. It will take fewer COB diodes to give you the same lumens as a spread or traditional panel, which means you can get high-powered COBs in much smaller sizes than other LED grow lights.

While they offer crazy intensity, the issue with COBs lies within their limited spectrum availability. These are available primarily warm 3500k spectrums and cool 6000k spectrums, but nothing in the way of multi-colored wavelengths, IR, or UV spectrums. However, if you’re looking for a grow light with huge intensity out of a small light, COBs are the way to go.

Primary vs. Supplemental Lighting

Like the names imply, LED grow lights can either be your plants primary source of light, or they can be used to supplement the lights you’re already using.

Your primary lights will have the most significant impact on your plants. Therefore, you’ll want to ensure these lights offer plenty of strength to stimulate plant growth.

At the lower end of the scale you’ll see 210w LED grow lights that offer peak PPFD at 455 or higher, which is good for a single flowering/fruiting plant.

On the higher end, you have 1000w lights that pump out over 1700 PPFD, which is more than enough for 2 to 3 mature fruiting plants per light.

As far as their spectral availability, primary lights come with an array of multi-colored spectrums, as well as white color temperatures. Some primary lights offer 1 spectrum, while other lights have the ability to adjust spectrums. The Kind LED K5 Series XL750, for example, has programmable wavelengths to offer plants all-red, all-blue, all-white, or a mix of wavelengths depending on the stage of growth. No matter what spectrum of light you give your plants, make sure your primary light has all the wavelengths they need.

Supplemental lights, on the other hand, are made to supplement your primary lighting. You can use them to fill in dark areas around your grow room when your primary lights can’t reach. They’re also perfect for seedlings, clones, and young plants because they give them enough light to grow without overwhelming them.

For example, the 50 Watt Advance Spectrum All Blue LED Grow Light Panel has over 100 low-wattage chips. These will help fill in gaps of light around your plants during the vegging stage, and can give you enough light for smaller plants like clones and seedlings.

In general, supplemental LEDs are great at giving your plants an additional amount of lumens and wavelengths they need. If your primary light can’t give your plants all the lumens or wavelengths they need, using one or more lower-powered supplemental LED grow lights will help your plants get all the light they need to thrive.

How to Choose the right LED grow light for your plants. Now that we are sure you know led grow light super well.

In this post, we will rrecommend two best full spectrum led grow lights for you.

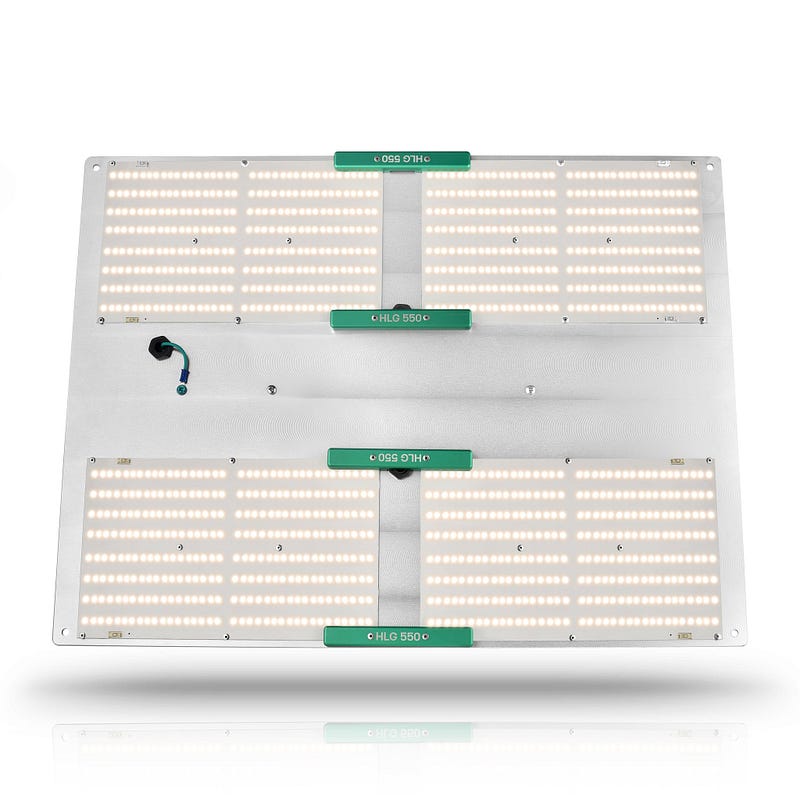

Horticulture Lighting Group LED Grow Light High efficiency HLG-550 V2 Quantum Board

This is one of HLG LED grow lights

The HLG550 V2 ECO indoor Horticulture LED grow light is designed to replace a single-ended 1000watt HID. ECO Model of HLG 550 offers highest output and efficiency for your money. This unit is dimmable, with wattage output from 240 to 500 watts. 3000K Spectrum recommended for flowering and 4000K recommended for Veg.

Coverage Area

Veg Footprint: 6' x 6'

Flower Footprint: 4.5'X4.5' or 5'X5'

Top Features

High efficiency white light Quantum Boards

Full-spectrum for better results

Reliable passive-cooled design

Better canopy light penetration with diffused light

Dimmable power supply included

Specifications

Power 240–500 Watts

Voltage Range 90–277 VAC

LED 1152 pcs Samsung 301B

Flowering Footprint 4.5'X4.5' or 5'X5'

Veg Footprint 6' x 6' at 36”

System Efficiency 171 Lm / W

System PPF Efficacy 2.5 μmol/joule

Dimensions 26"X20"x3"

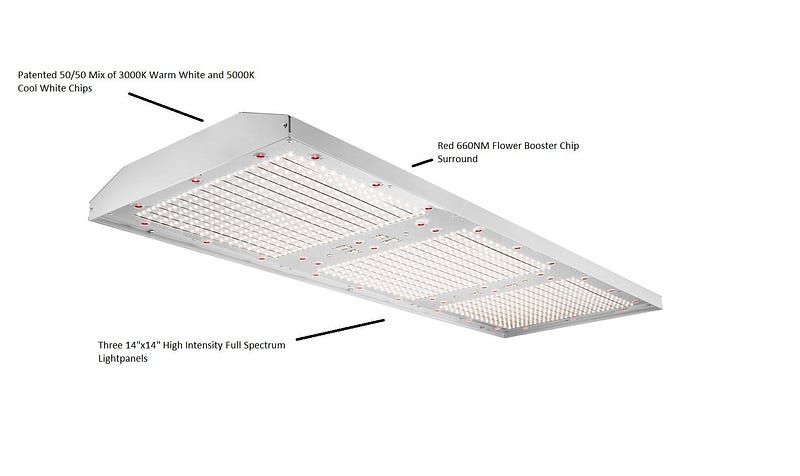

FGI Lightpanel 500 LED Grow Light

This is one of FGL LED grow light

The FGI Lightpanel 500 is newly powered with the latest 2021 chips. Upgraded diodes create up to 1326umols of PAR.

Suitable for both full scale commercial growing or home use in tents and small rooms, the Lightpanel 500 will exceed your expectations.

At 44" long it easily covers a 4' grow tray and up to 5' of mature canopy. Install three over a 4' x’ 8' grow area and save 33% energy as compared to a pair of traditional HID grow lamps. Growers report up to 1.9 GPW with this super efficient high yielding light.

Enhanced Functionality

The FGI Controller allows for a robust fully passive hard wired interface to our bundled FGI Controller. Simple plug and play connections using standard CAT6 network cable.

Adjust warm white diodes, cool white diodes and red channel for spectrum tuning and dimming.

Conclusion

When LED lights for growing first hit the market several years ago, horticulturists everywhere were intrigued, but not convinced, that it could be the answer to their plants’ dreams. Back when they first debuted, they were expensive, and not nearly powerful enough to get the growth gardeners wanted from their plants. A lot’s changed, though, and many growers are making the switch.

The thing is, LED grow lights have come so far that they are far and away the better choice, but only in certain circumstances. If you’re just getting started with indoor gardening, it’s a good idea to start off with LED grow lights. They are pricey, at first, but they pay off in the long run.