MOZLEY Desanding Hydrocyclone as solids-water seperator efficiently and reliably removes solids from fluid streams. Fully packages designs are scalable to meet size requirements and can be fully automated to provide efficient,compact,solid-liquid seperation capabilities,including solids removal from produced water streams.

Overview – MOZLEY Desanding Hydrocyclone

- Remove solids from fluid streams with a range of properties

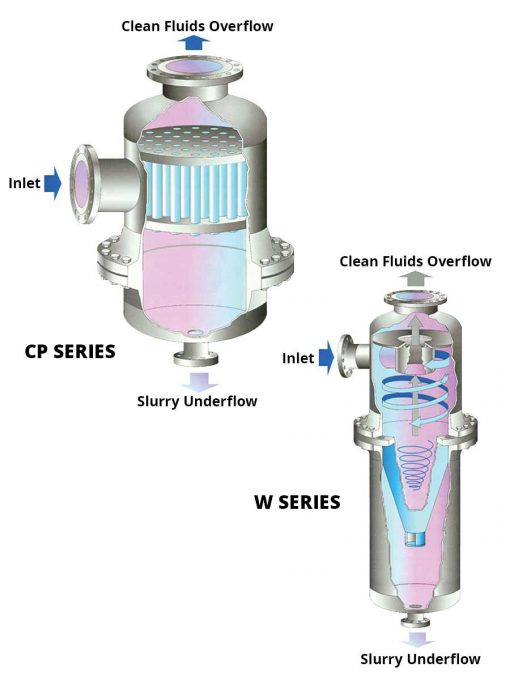

The MOZLEY Desanding Hydrocyclone solids-water separator is a versatile technology based on an optimized internal geometry that can accommodate a range of solid types and concentrations, fluid rates, pressures, and temperatures. This makes MOZLEY separators well-suited for the unique applications found in the oil and gas industry, including treatment of produced water, aquifer water, and deballast water; hydrocarbon desanding; and other sand cleaning operations.

Manufactured from abrasion-resistant ceramics that provide enhanced wear resistance and longer life, MOZLEY separators are designed to increase solids removal and reduce downstream issues while still allowing full production.

- Handle high flow rates with a compact system

Many hydrocyclones can be packed into a single vessel, resulting in a high unit flow rate. There are no moving parts in a vessel and operate continuously with minimum supervision and maintenance. Sand separation can be a fully automated with continuous or batch discharge of solids, with or without sand accumulation.

- Special features :

- Separation of 98% of particles from 3 to 108 um

- Flow rates from 25 to 100,000 bbl/d [3 to 11,924 m3/d] of water

- Pressure drop of 10 psi [0.07 MPa] from inlet to overflow outlet

- Customizable solutions for your solids challenges

The performance of a hydrocyclone depends on the pressure drop across the inlet and overflow outlet and the volume split to underflow. In general, a higher pressure drop yields a higher capacity and sharper separation.

Thus, the diameter of a hydrocyclone influences the size of solids removed. MOZLEY Desanding Hydrocyclone separators are available with individual hydrocyclone sizes ranging from 0.5 in to 30 in, with 2-in or 3-in ceramic desanding hydrocyclones standard for most applications.

The larger diameter, single-liner units offer high flow rates, but are not as efficient at removing smaller solids as narrower-diameter units that have multiple liners in a single vessel. Because of this, the diameter of hydrocyclone is selected based on the size of solids targeted for removal, with further optimization achieved by tailoring aspects such as inlet and outlet diameter. Construction material can also be matched to the solids expected in the system, for instance polyurethane for low-temperature applications, or extremely abrasion-resistant ceramic materials to address highly erosive solids.

Matching the most suitable hydrocyclone geometry with construction materials that can best address the characteristics of the process fluid and suspended solids creates a customized separation solution for most applications that will deliver reliability and efficiency over alternatives.

Application of MOZLEY Desanding Hydrocyclone

The solids-water separator operates via pressure drop. Fluids are directed along an involute into the desander, which causes the fluid to spin. Strong centrifugal forces are generated by the spinning motion, causing the solids and liquid to separate. The centrifugal force generated in a hydrocyclone varies over its length and may reach a maximum of 2,000 g. Heavier solids are forced outward toward the wall of the hydrocyclone, and the lighter fluids migrate toward the center core. Because of geometric variables and flow patterns, the lighter fluids flow through the overflow, and the heavier solids are directed to the underflow. The result is a process with a retention time of typically 2 to 3 seconds. Hydrocyclones provide simple and effective means of achieving effective separation of solids and sand from produced and other water streams.For removing solids from a production system, desanders can be utilized either upstream or downstream of a production separator. The typical location is downstream of the production separator on the water outlet and upstream of the water level control valve. The majority of the sand is accumulated in the separator and will travel out with the water stream. This water outlet is located on the bottom center position of the separator to minimize solids buildup.

https://www.gmsthailand.com/product/mozley-desanding-hydrocyclone/