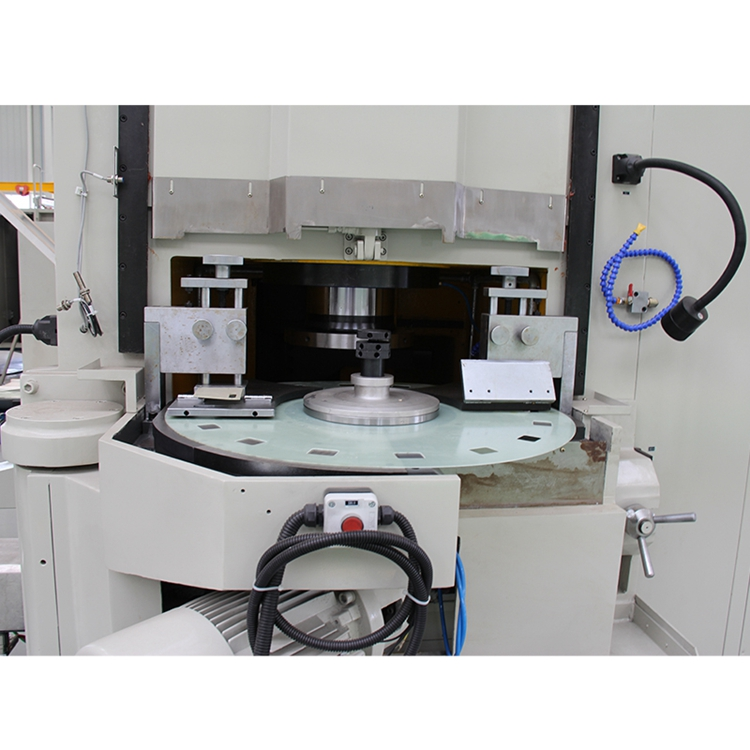

Keep Your Precision Vertical CNC Grinder Cool: Maintenance Methods for Optimal Use

It working optimally in case it's important to keep you have precision vertical CNC grinder. Being among the most essential elements of the grinder may be the device that is cooling. We will protect the advantages, innovation, safety, use, and service of cooling devices for precision vertical CNC grinders.

Advantages of Cooling Devices

Firstly, let's talk regarding the advantages of cooling devices. Cooling devices with Vertical CNC Double disc Grinder prevent temperature accumulation in your grinder's spindle, which is really a must for optimal performance. Additionally they lessen the use and tear on your own machine's components, prolonging its lifespan. Also, they assure consistent cutting results, preventing any harm towards the workpiece.

Innovation in Cooling Devices

In terms of innovation, cooling devices have actually developed Double Surface Grinding Machine particularly through the years. Contemporary cooling systems offer advanced features such as automatic heat control, continuous monitoring, and lubrication that is automated. These features assure the procedure that is efficient of machine while also reducing the chance of malfunction or harm.

Safety Considerations

Shifting to safety, cooling devices can be an safety that is essential for precision vertical CNC grinders. Coolant fluid can dissipate heat generated during the process that is grinding reducing the possibility of thermal deformation associated with the spindle. This guarantees a safer working environment for operators.

Using Cooling Devices

Using devices that are cooling relatively easy. The action that is first to ensure the fluid level is enough. The fluid should be without any certanly contaminants and debris to prevent obstructions inside the coolant bloodstream supply. Use the recommended coolant type and concentration for the machine to produce performance that's certain is optimal. Also, it's crucial to retain the coolant heat within advised range.

Maintaining Quality

Maintaining the quality of the device that is cooling is for optimal performance. Regular cleaning and assessment of the cooling system are necessary to make sure your machine operates optimally. This includes checking for leakages, cleaning out from the filter and pump, and ensuring the coolant reaches the level that's right.

Application of Cooling Devices

Finally, allow's talk concerning the application of cooling devices. Cooling devices of CNC Grinder Machine are required for the number of grinding operations, including precision surface grinding, cylindrical grinding, and jig grinding. The surface is improved by them finish of the workpiece while also reducing the risk of thermal damage.