Industrial barcode printers are designed for harsh environments and they offer a suite of advantages that cater to the demanding needs of various sectors. Here, we delve into the seven most significant benefits of these robust machines, highlighting their pivotal role in enhancing productivity and reliability.

Durability and Robustness

Industrial barcode printers are engineered to thrive in challenging environments. Their robust construction makes them resistant to dust, moisture, and extreme temperatures.

For instance, in the demanding environments of warehouses and workshops, they consistently deliver high-quality prints amidst the dust and activity of a busy warehouse or the fluctuating temperatures and vibrations of a workshop floor. This ensures that crucial labeling for inventory, tools, and machinery remains clear and legible, facilitating efficient tracking and management of resources in these challenging settings.

High-Volume Printing Capability

The ability to handle high-volume printing is another standout feature. In the fast-paced world of retail logistics, managing vast inventories is a daily challenge.

Industrial barcode printers rise to the occasion, efficiently processing thousands of labels for products, aiding in swift sorting and dispatching. This capability not only speeds up operations but also reduces the likelihood of errors, ensuring that the right products reach the right destinations.

Precision and Quality

Precision in printing equates to accuracy in scanning. These barcode printers offer high-resolution outputs, essential for producing barcodes that are easily readable by scanners. This precision is crucial across sectors, from manufacturing to healthcare, where the accuracy of barcode information can be critical.

Versatility in Label Media Handling

The ability to print on a diverse range of materials is a significant plus. Whether it's heavy-duty labels for outdoor equipment or heat-resistant tags for automotive parts, industrial barcode printers adapt to various printing needs, offering businesses the flexibility to label different types of products.

Advanced Connectivity Options

Integration into existing networks is seamless, thanks to advanced connectivity features like Wi-Fi and Bluetooth. This connectivity ensures that printers can be easily controlled and monitored from central systems, streamlining the printing process and enhancing workflow efficiency.

Scalability and Customization

Tailoring to specific industry requirements is straightforward with these industrial printers. They support various barcode standards and can be configured for different label sizes, making them suitable for a wide range of applications, from small-scale boutique operations to large manufacturing plants.

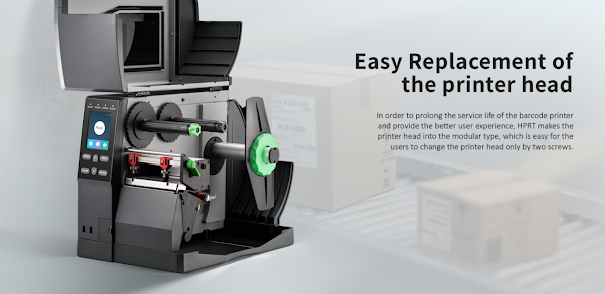

Ease of Maintenance

Despite their sophisticated functionalities, these barcode printers are designed for straightforward maintenance. Their modular design, exemplified by features like the HPRT printhead, allows for quick parts replacement, minimizing downtime and keeping operations running smoothly.

So, what's the final word on industrial barcode printers? With their robust build and ability to handle massive print jobs, they're indispensable. With the widespread adoption of RFID technology, industrial barcode printers are not merely adapting; they are leading the innovation wave. By integrating RFID, these printers are enhancing efficiency, showcasing how they stay ahead in the technological evolution.