In many cases, if you neglect the application of the metal laser cutting machine to control it, it will incur more costs, so this is the important reason why users are expected to have a few ways to control its capital. Let’s analyze how to effectively control the using cost of metal laser cutting machine.

Ways to reduce the application cost of metal laser cutting machine:

1. Minimize the number of times the laser is turned on and off during normal operation of the metal laser cutting machine. If the metal laser cutting machine is not used at ordinary times, the laser can be turned off. In addition, if the cutting requirements can be met, the applied power should be reduced as much as possible to save electricity cost.

2. Metal laser cutting is applied strictly in accordance with the operating rules. The metal laser cutting machine is a high-tech equipment. Improper application will affect the system of the whole machine, resulting in unstable quality of the cut workpiece, and severely affecting the quality of the equipment. This is not worth the loss.

3. The focusing lens of the metal laser cutting machine is cleaned. The focusing lens is the lens that touches the processing surface. During the operation of the laser cutting machine, a little metal slag and dust will be generated, which will adhere to the focusing lens. If it is not cleaned in time, it will lower the light transmittance and increase the heat absorption, which will affect the accuracy of cutting, and even cause damage to the lens. Timely cleaning of the focusing lens can reduce unnecessary material spreading and the cost of replacing the lens.

4. After the metal laser cutting machine works for a long time, there will be abrasion between the various parts, which will cause the instability of the equipment and affect the cutting accuracy. Therefore, the maintenance of the equipment is also a way to extend the application life of the equipment and improve the cutting accuracy.

5. Nearly 80% of the application of laser cutting machine is from the consumption of gas. It is the main energy supply for laser cutting machine and CNC laser cutting machine. Familiar with and inquiring about the gas application principle of laser cutting machine will help to reduce the cost of gas.

Pay more attention to the maintenance of the equipment in the operation, on the one hand, it can reduce the application cost of the metal laser cutting machine, on the other hand, it can extend the application life of the equipment to ensure the quality of equipment cutting.

IGoldenlaser provides CNC Fiber Laser Metal Cutting Machine,CO2 laser cutting machine,CO2 Laser Engraver,laser marker with Complete Functions.14+ Years Experience With Cost-Effective Price And Professional Technical Patent. Laser Pipe Cutter Machine。

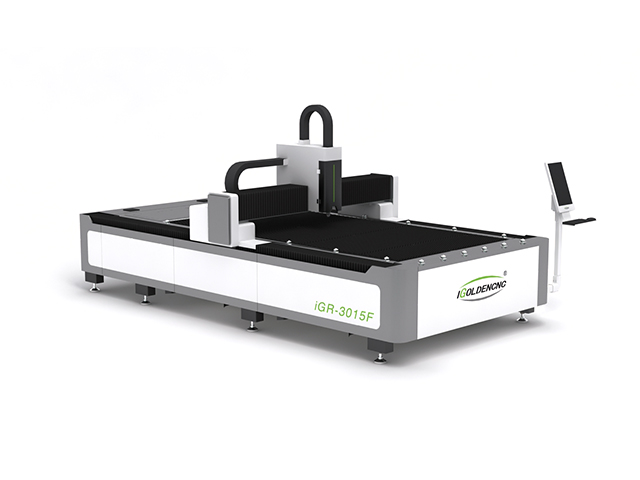

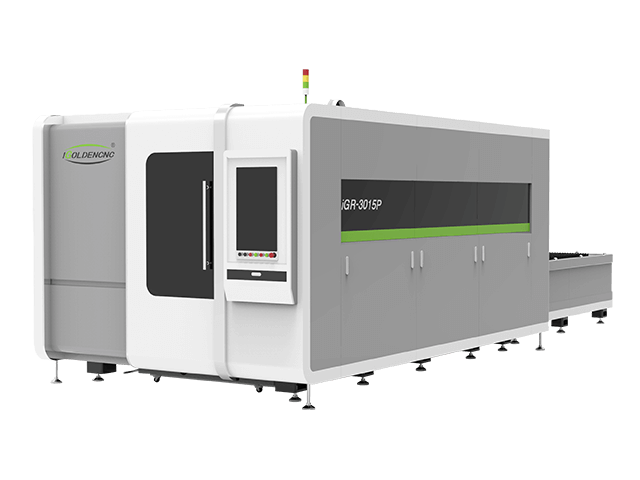

Fiber Laser Metal Cutting Machine

The entry-level laser cutting machine, really cost-effective, open-type, single platform, simple structure, convenient installation, high precision, fast speed, simple operation, convenient maintenance, affordable equipment, low operating cost, it is a sheet metal processing enterprise customized product.

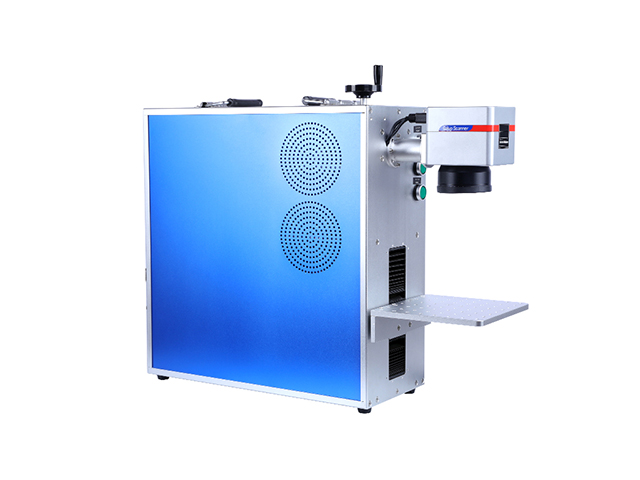

Laser Marker

Entry-level stable model, high precision, high speed, equipped with dual-purpose foot support for moving flexibly, it is the model with the largest market share.

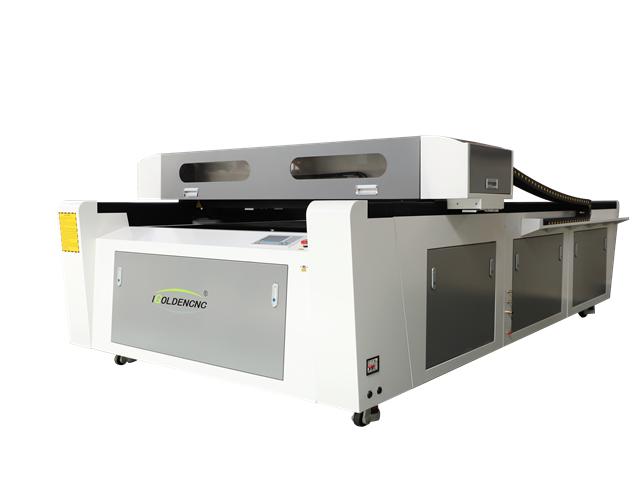

CO2 Laser Engraver